Ansys simulation software is extensively validated across multiple industries and applications. These simulation tools provide accurate and reliable data that drastically reduce manufacturing costs and test time. Additionally, Ansys simulation software is built with an emphasis on streamlined, intuitive workflows that give engineers more time to focus on critical design decisions. The fact that Ansys flagship products are agnostic to computer-aided design (CAD) and blade design tools provides utmost flexibility for designers to use any blade design tools from Ansys' partners.

Comprehensive Multiphysics Solutions in One Portfolio

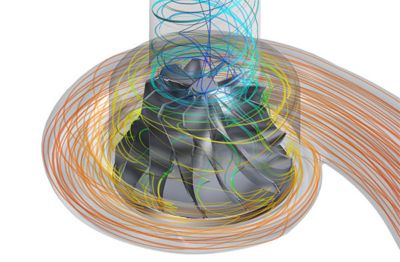

As we look at the whole machine solution, simulation capabilities include fluids, thermomechanical, structural and, of course, multiphysics solutions that leverage Ansys flagship products such as Ansys Fluent, Ansys CFX, Ansys Mechanical, Ansys FENSAP-ICE and Ansys LS-DYNA. As you begin to simulate and analyze these multiphysics applications, you need to ensure accurate and efficient data transfer between the solvers. Our platform allows all Ansys solvers to accurately and efficiently transfer and map data, which results in the most robust and accurate multiphysics simulations for aeromechanics, fluid–structure interaction, conjugate heat transfer modeling, foreign object damage assessment and blade-out (burst) analysis.

Advanced Physics to Design the Next Generation of Turbomachines

To realize designs that meet performance and regulatory requirements over a wide range of operating conditions, Ansys provides unique capabilities to tackle the most advanced physics. Ansys equips designers with tools to accurately predict complex physics such as pump cavitation, fan/compressor icing, combustor–turbine interaction and the acoustics behind fan noise.

Understanding the operating range of the pump where cavitation begins is critical. High-fidelity cavitation models in CFX and Fluent, such as Rayleigh-Plesset in combination with advanced multiphase and turbulence models enable turbomachinery manufacturers to accurately predict the pump operating limits beyond which cavitation occurs and becomes substantial.

In the context of designing long-life gas turbine blades and vanes with optimized cooling patterns, Ansys makes it possible to accurately predict hot-streak migration through the high-pressure turbine (HPT) stages. Designers can model joint and/or co-simulation of the combustor and the HPT. Combustor–turbine vane modeling with conjugate heat transfer is performed in a single simulation for accurate hot-streak tracking using high-fidelity scale-resolving turbulence models. This leads to accurate thermal management of blades and vanes, and significant improvement of turbine durability.

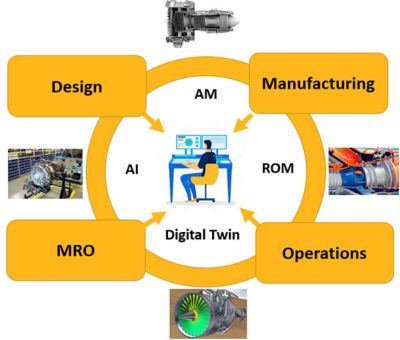

A Streamlined and Automated Simulation Process in the Product Life Cycle

Ansys is pervasive in the design process, and now Ansys simulation extends into manufacturing, operations, and MRO (maintenance, repair and overhaul), making simulation pervasive throughout the product lifecycle with feedback into the design process. Leveraging additive manufacturing helps push the boundaries of conventional designs and unlocks tremendous possibilities in design for manufacturability.

MRO spending on turbomachinery is significant and, in many cases, much higher than the original machine purchase price. Hence, the ability to predict when maintenance is needed provides significant advantages to OEMs and their customers. Ansys has a range of ROM capabilities that can be effectively used for predictive maintenance. The image below highlights how Lufthansa Technik uses flight data and simulations to build field ROMs that can predict failures of critical gas turbine engine components. The simulation workflow in this case included aero-thermal analysis using CFX and Mechanical. Statistics on Structures (SoS) technology in Ansys optiSLang is used to perform sensitivity studies on selective flight data to build field metamodels. These field ROMs accurately predict temperatures, stresses and strains in real time, enabling evaluation of the remaining life of critical engine components.

No comments:

Post a Comment