Think of the ocean as the world’s biggest battery. That’s what CorPower Ocean does. The Swedish firm has developed a wave energy technology that heaves with the movement of the waves. As they do, patented technologies inside the buoys transform the ocean’s wave energy into clean, renewable electricity that can power hundreds of thousands of homes and businesses. And unlike wind or solar energy generation systems, CorPower Ocean’s buoys doesn’t stop generating electricity when the sun sets or the wind settles. The buoys ride the swell of the waves — a more reliable and predictable power source — day and night, helping to balance the grid with clean electricity.

A CorPower Ocean wave energy farm. Image courtesy of CorPower Ocean

Like any technology designed for use at sea, success depends upon the technology’s ability to perform properly under variable and unforgiving conditions. Yet as in any young company with a big idea and a small budget, it’s not possible (or even desirable) to build, haul out to sea, and test prototypes of every single technology or buoy design variant that the company’s engineers might propose. How best to cost-effectively ensure that designs will survive and perform reliably in these conditions? CorPower Ocean’s engineer’s rely on simulation tools from Ansys.

Simulating Surges by the Sea

With an easily exploitable global potential of 500 GW, a figure comparable to today’s cumulative hydro capacity — and even surpassing the todays’ nuclear capacity — wave energy stands out as one of the world's largest untapped source of clean energy. CorPower Ocean’s wave energy converters are designed to be tethered to the sea floor, and a CorPack cluster of buoys can produce 10 MW–20 MW of electrical energy. Multiple CorPack clusters can be linked — all sharing a common electrical transmission infrastructure — to deliver gigawatts of electricity.

The buoy is tethered to the seafloor via a patented anchoring technology. A cable links multiple buoys and passes clean electrical energy into the local grid. Image courtesy of CorPower Ocean

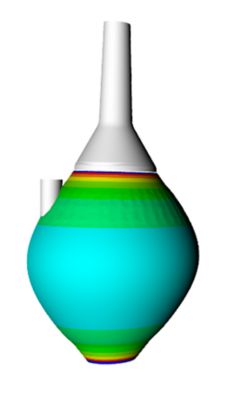

CorPower Ocean’s designers even used Ansys Composite PrepPost simulations to determine the optimal combination of filament materials and winding patterns that would be used to wrap the composite materials of which the buoy hulls are constructed. Using a design of experiments approach, they ran optimization studies to determine which combination of filaments, wound at different angles, would produce the lightest yet strongest hulls. They then passed these optimization specifications to the software controlling the filament winding systems in CorPower Ocean’s mobile factory system, which enables CorPower Ocean to construct the composite hulls at the location where the buoys are to be deployed. That has eliminated the need to transport the buoys from what would normally be a distant manufacturing facility to the location where they are to be installed.

Simulation mesh structure of a composite joint in a CorPower Ocean buoy. Image courtesy of CorPower Ocean

Wave Goodbye to Large-scale Prototyping

While CorPower Ocean has built and operated at sea a half-scale device, and is progressing with its full-scale proof-of-concept deployment in Agucadoura, Portugal, the company has been able to rely on simulation to avoid the need to build and test prototypes every time a design refinement is proposed. Early physical tests involving a few key prototypes effectively validated the outcomes projected in simulation. This enabled the engineering teams to feel confident that the outcomes indicated by simulation were predictive of what would actually occur in the real world. The effect has been to accelerate design — for CorPower Ocean engineers do not need to wait for prototypes to be built, delivered, towed out to sea, and tested; they can see the results in simulation within minutes or hours — as well as to reduce the cost of design. This both accelerates delivery of optimized, customer-ready products and ensures that CorPower Ocean can offer those products at a price that customers can cost-justify, even when planning very large-scale deployments.

ACP composite modeling winding pattern mapping. Here CorPower Ocean can accurately define the ply definition of its winded products.

As the buoy rises and falls on ocean waves, technology within the buoy converts wave energy into rotational energy that generates electricity. Image courtesy of CorPower Ocean

“We’re ultimately building large, complex generation systems,” says Verdeguer. “The more you can catch problems and optimize outcomes in the design phase, the more effectively you can de-risk a project.”

As the world races to embrace clean, renewable energy sources — particularly ones that can reliably produce green energy on a 24/7 basis — speeding up design while simultaneously de-risking the project is definitely a good thing.

No comments:

Post a Comment